A

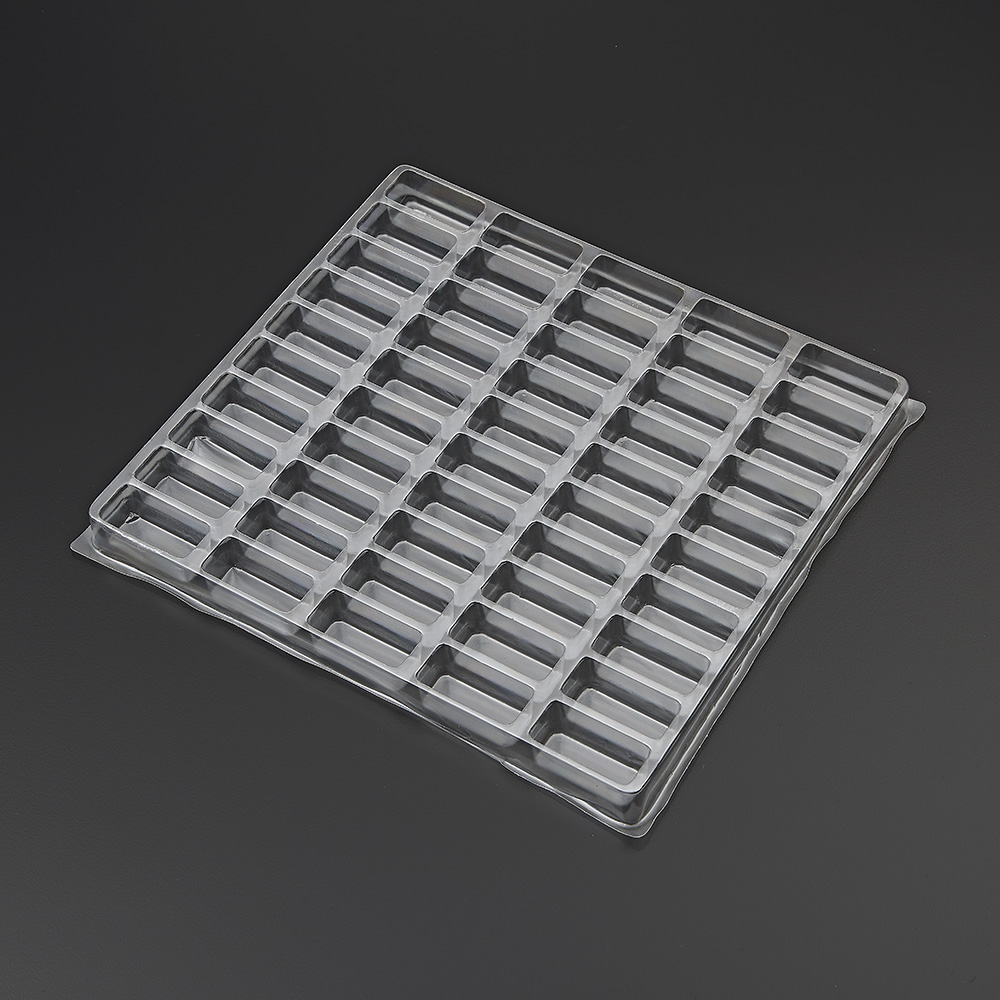

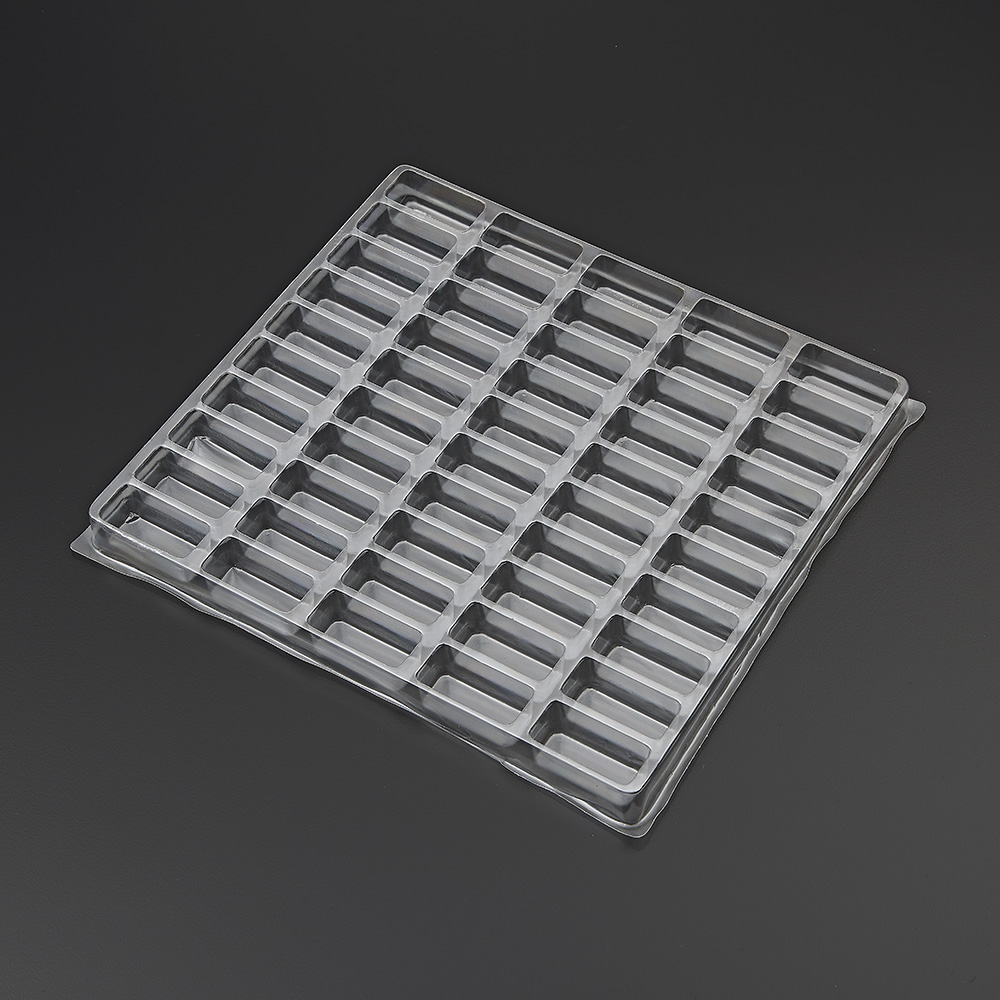

It has heat resistance (60 ~ 85 ℃), water and oil resistance, light texture and high toughness. It does not contain toxic substances after heating, so it is widely used in food and industrial fields. Often used in Pote bottles, industrial packaging, TRAY disks, etc.

Main features:

1. Excellent transparency: PET has extremely high transparency and is usually used in packaging applications that require visual presentation products.

2. Heat resistance and chemical stability: PET has good heat resistance, can work stably at higher temperatures, and has excellent resistance to most chemical substances (such as oils, acids, alkalis, etc.).

3. Environmental protection: PET is a recyclable material and can be recycled and recycled after recycling, making it environmentally friendly.

Summarize

PET is a polymer material with excellent properties, with high strength, good transparency, heat resistance, chemical stability, and recyclability. It has been widely used in packaging, fiber, electronic products, automobiles and other industries, and with the improvement of environmental awareness, the recycling and reuse of PET plays an increasingly important role in modern industry. Whether in daily life or in high-tech fields, PET is a material of important value.